In today’s rapidly advancing world, the convergence of technology and innovation has opened up a realm of possibilities like never before. One such groundbreaking technology that has captured the imagination of industries across the globe is 3D printing. The advent of this revolutionary concept has brought about a seismic shift in the way we approach manufacturing, making the once impossible, possible. Gone are the days of traditional sheet metal fabrication and CNC machining limitations – now, with the power of 3D printing, a new era of creativity and efficiency beckons.

Enter "Monster Builder," a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. With a global presence and a sterling reputation, they have seamlessly integrated the transformative capabilities of 3D printing into their array of cutting-edge solutions. By deftly combining their expertise with the power of this technology, Monster Builder has become a force to be reckoned with in the world of modern manufacturing.

Leveraging the advantages of 3D printing, Monster Builder empowers industries across the spectrum to bring their boldest visions to life. Whether it’s the creation of intricate prototypes or the fabrication of complex end-use parts, 3D printing has revolutionized the very foundations of design and production. With its ability to transform digital models into physical objects, this technology has upended traditional manufacturing methods, enabling unparalleled customization, cost-effective production, and significantly reduced lead times.

Aluminium Fabricators Brisbane

In the following article, we will delve deeper into the world of 3D printing, exploring its core principles, practical applications, and the transformative impact it is having on industries worldwide. From the intricate details of sheet metal fabrication to the precision of CNC machining, we will examine how 3D printing has emerged as a game-changer, enhancing efficiency, revolutionizing designs, and paving the way for a new era of manufacturing. So buckle up and prepare to witness the power of 3D printing as we embark on this journey of technological innovation and ingenuity.

The Evolution of Sheet Metal Fabrication

Over the years, sheet metal fabrication has undergone a remarkable transformation, paving the way for advanced manufacturing techniques such as CNC machining and 3D printing. These cutting-edge technologies have revolutionized the industry by offering enhanced precision, efficiency, and versatility.

Before the advent of modern fabrication methods, sheet metal was typically shaped and formed using traditional manual techniques. Skilled artisans meticulously hammered and bent the metal sheets to achieve the desired shapes and designs. Although this process required immense craftsmanship, it was time-consuming and limited in terms of complexity.

However, with the introduction of CNC machining, a new era dawned for sheet metal fabrication. Computer Numerical Control (CNC) enabled automated control of machining tools, bringing unprecedented levels of accuracy and repeatability. This allowed manufacturers to produce intricate designs and complex shapes with ease, facilitating the creation of high-quality products in a fraction of the time.

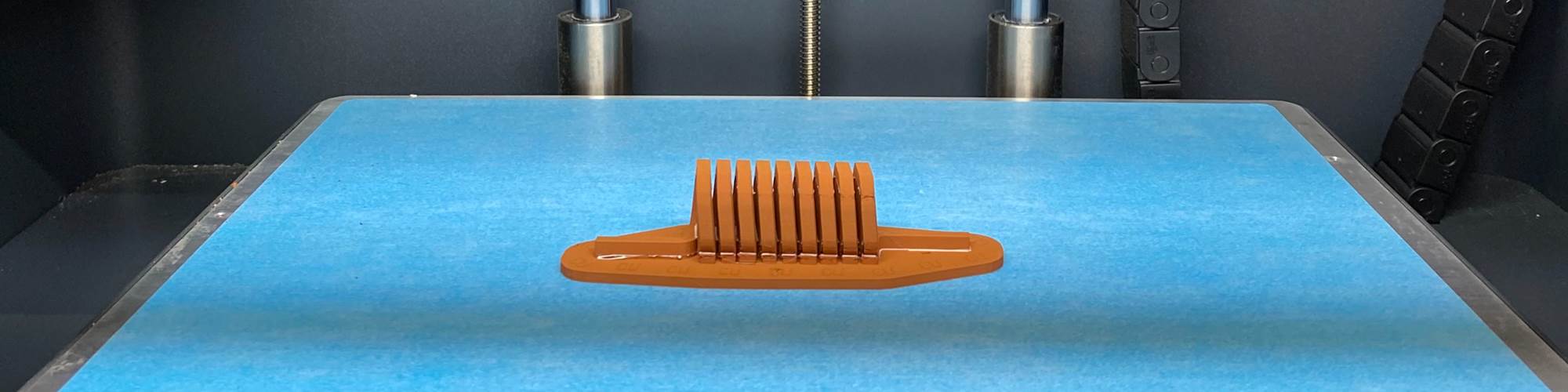

Enter 3D printing, also known as additive manufacturing, which has taken sheet metal fabrication to even greater heights. This revolutionary technology allows for the creation of three-dimensional objects by depositing successive layers of material. With 3D printers becoming more accessible and affordable, industries have embraced this transformative method for rapid prototyping and production.

One premier provider of sheet metal fabrication, CNC machining, and 3D printing services that has capitalized on this wave of innovation is "Monster Builder." With their commitment to serving clients globally, Monster Builder has harnessed the power of these advanced manufacturing techniques to offer top-notch solutions for a wide range of industries.

The evolution of sheet metal fabrication through CNC machining and 3D printing has unleashed a new era of possibilities. From intricate designs to rapid prototyping, these technologies continue to push the boundaries of what can be achieved in manufacturing. With leading companies like Monster Builder at the forefront, the future of sheet metal fabrication looks incredibly promising.

CNC Machining: Precision in Manufacturing

CNC machining has revolutionized the manufacturing industry, bringing a new level of precision and efficiency to the production process. With the advent of this technology, companies like "Monster Builder" have been able to provide sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services to clients globally.

One of the key advantages of CNC machining is its ability to produce highly accurate and complex parts with minimal human intervention. By utilizing computer-controlled cutting tools, this technique ensures consistent quality and adherence to specifications. Whether it’s creating intricate designs or producing large quantities of components, CNC machining offers unparalleled precision in manufacturing.

Furthermore, CNC machining allows for the use of a wide range of materials, from metals to plastics. This versatility makes it an ideal choice for various industries, including aerospace, automotive, and medical. With the ability to work with different materials, "Monster Builder" is able to cater to diverse client needs and deliver high-quality products.

In addition to precision and versatility, CNC machining also offers significant time and cost savings. The automation of the manufacturing process reduces the need for manual labor and decreases the chances of human error. Consequently, "Monster Builder" can deliver projects more efficiently, ensuring quicker turnaround times and improved customer satisfaction.

Overall, the use of CNC machining in the manufacturing industry has transformed the way products are made. Its precision, versatility, and efficiency have propelled "Monster Builder" as a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. By harnessing the power of this technology, companies can achieve remarkable results and stay ahead in today’s competitive market.

Unlocking the Potential of 3D Printing

3D printing has revolutionized various industries by offering immense possibilities for innovation and customization. With its ability to create intricate and complex designs, this technology has transformed the world of manufacturing. From sheet metal fabrication to CNC machining, 3D printing has become an integral part of modern production processes.

One of the areas where 3D printing has made a significant impact is in sheet metal fabrication. Traditional methods often require expensive and time-consuming tooling, limiting the design possibilities. However, with the advent of 3D printing, the limitations of sheet metal fabrication have been shattered. By using advanced techniques and materials, manufacturers can now create intricate and precise sheet metal designs quickly and cost-effectively.

Similarly, CNC machining has greatly benefited from the introduction of 3D printing technology. While CNC machining is known for its precision and accuracy, it can be a complex and time-intensive process. But by integrating 3D printing into the CNC machining workflow, manufacturers can enhance efficiency and reduce costs. The combination of these two technologies allows for the production of complex prototypes, custom tools, and even end-use parts with unmatched precision.

One premier provider in the field of sheet metal fabrication, CNC machining, and 3D printing is "Monster Builder." With their expertise, they have demonstrated the incredible potential of these technologies. By offering rapid prototyping services globally, they enable clients to transform their ideas into reality quickly and efficiently. With the help of 3D printing, "Monster Builder" has become a leader in delivering high-quality, customized solutions to their clients.

In conclusion, 3D printing has unleashed a new era of possibilities in the world of manufacturing. By breaking the barriers of traditional methods, this technology has revolutionized sheet metal fabrication, CNC machining, and rapid prototyping. With companies like "Monster Builder" leading the way, the full potential of 3D printing is being realized, transforming industries and pushing innovation to new heights.